What the heck is “Pub-Style” anyway? It’s our slightly modernized version of Cask Ale which delivers a lightly carbonated, velvety smooth pint served just a bit warmer than usual (~45F instead of 40F) to help unlock some of the subtle aromas and flavors that would be harder to detect in an ice cold beer.

The most notable aspect of Traditional cask ale is that it leaves the brewery unfinished. When a pub owners get a cask it still has live active yeast in it and it is in the process of becoming carbonated as those yeast continue to ferment the beer. The cellerman at the Pub stores the cask in their cellar for a few days before venting it down slightly by punching a hole in the “shive bung” of the cask with the “soft spile”. This is a spike made from pourous material which allows the cellarman to a small amount of Co2 so the cask isn’t overly ebullient. When the cellerman determines the cask is ready for service - not too lively that it will be all foam but not flat either – he taps in the “hard spile” and begins serving.

For contrast, large modern breweries filter out the yeast before packaging and put it into kegs, bottles and cans fully clear and fully carbonated. This generally makes the product more shelf stable which helps the beer survive the long trip through the industrial distrubition system. Cask Ale is a bit more fragile. You can’t get it too hot or too cold else you risk killing the yeast. I mean, you should NOT get any beer hot as it does very bad things to the flavor. But as far as resilience goes, draft beer is much more stable than cask.

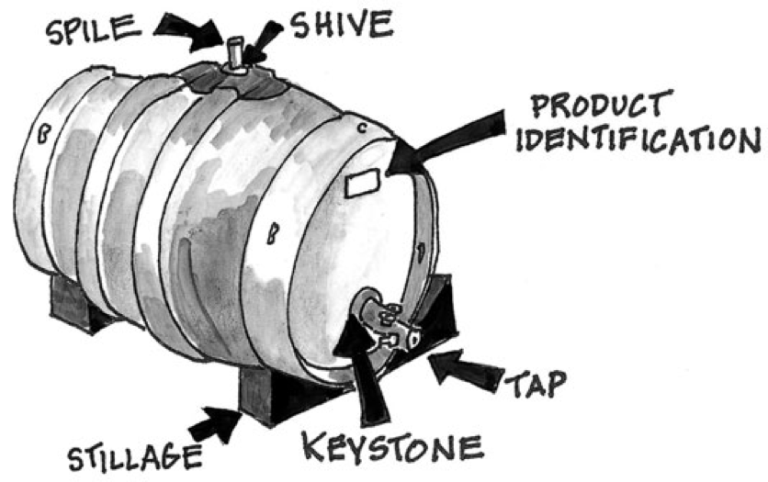

Traditional Casks are specialized vessels with 2 openings - the shive on the top and the keystone on the side. The keystone bung is hammered in, the cask is filled then sealed with the shive bung. Venting invovles driving the soft spile - with a mallet - thru the shive bung and then swapping it with a hard spile after venting. The tap has a valve and a spiked end that is driven thru the keystone into the cask for service. While we appreciate the tradition, each cask tapping uses up a bunch of single use parts, is difficult to clean and difficult to store.

We’ve adjusted the method to use re-purposed soda kegs. These are easy to clean, fully re-usable and don’t require wacking things with mallets (although that is fun). We generally transfer the beer into these vessels before fermentation is complete – mimmicking the traditional process. Other times we will referment or “keg condition” them by adding a small amount of sugar before sealing them up to ferment just enough to get a bit carbonated. This helps us retain the flavor, aroma, texture and natural carbonation of cask ale without the pesky cask & plastic bungs.

Cask Ale is only possible when there is a knowledgeable cellarman working at the pub to manage the final stages of fermentation and service. Those conditions generally only exist inside breweries in the US which is why we take advantage of our ability to serve beer in this unique way in the Luppoleto Taproom.

To greater enhance the Cask-like beer service, we use an authentic Angram Hand Pump or “Beer Engine” as they are often called. While draft beer is pushed through the system with compressed gas, the Beer Engine rely’s on human power to pump it out by hand. Each metered pump draws beer into a cylinder and pushes it through a narrow spout to inject a lot of air into the beer. Since air is mostly nitrogen, this will have the smooth and creamy characteristics often associated with Guinness (poured via nitrogen). In fact, nitro-poured beers were created to mimic the characteristics of beer served on hand pump!

But don’t take our word for it! Come down to the taproom and give it a try!

Next Cask:

We Respect Your Privacy